Roller Bit Uses: Everything You Need to Know

Roller bits are essential components in modern drilling operations, widely used in foundation drilling, piling, bore pile,well drilling, and oilfield exploration. Designed to withstand extreme ground

Bored piles, also known as drilled shafts, are a type of cast-in-place reinforced concrete foundation widely used in deep foundation construction. Common in high-rise buildings, bridges, and industrial facilities, bored piles are poured directly on-site, unlike precast piles such as rotary or square concrete piles. Ideal for heavy load-bearing structures, bored pile foundations offer excellent stability and adaptability to complex ground conditions, making them a reliable solution for large-scale construction projects.

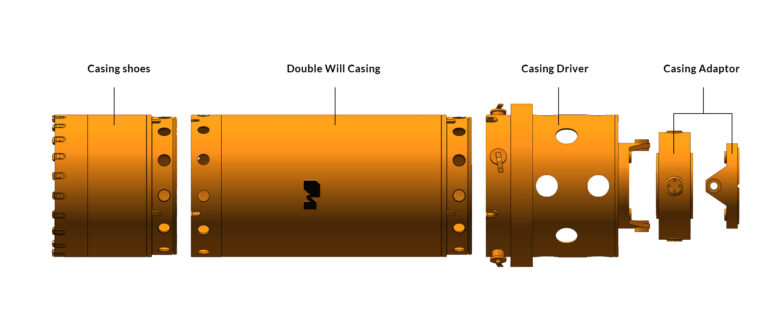

The bored pile construction process is a widely used deep foundation method designed for heavy load-bearing structures such as high-rise buildings, bridges, drilling, piling works, water well drilling and industrial facilities. It involves rotary drilling into the ground using specialized tools like the core barrel, drilling bucket, or auger, depending on the soil and rock conditions. In soft or collapsing soil conditions, a piling casing is typically inserted to maintain borehole stability. Reinforcement is then placed into the borehole, followed by cast-in-place concrete pouring to form a strong, reliable foundation. This process ensures precise pile formation and is ideal for projects requiring high accuracy, depth control, and adaptability to complex ground conditions.

Bored pile construction faces several challenges, especially in complex soil conditions like soft clay, collapsing ground, or water-bearing layers.Common issues include borehole instability, improper casing installation, reinforcement placement errors, and concrete segregation. Understanding these challenges is key to ensuring safe and efficient bored piling for deep foundations, high-rise buildings, and infrastructure projects.Bored pile construction presents various challenges in different ground conditions, including soft soil, collapsing layers, water-bearing strata, and hard rock formations. Issues such as borehole instability, casing difficulties, tool wear and reinforcement misalignment can impact project safety and efficiency. Understanding these bored piling challenges is essential for successful deep foundation work in high-rise buildings, bridges, and large-scale infrastructure projects.

Bored pile construction is a popular method among various types of piles, known for its ability to form strong and stable drilled shaft foundations. As a cast-in-place concrete piling foundation, it reduces noise and vibration during installation, making it ideal for urban and sensitive environments. Bored piles can reach great depths and are highly adaptable to different geotechnical conditions, offering a durable solution for complex foundation needs in modern construction.

Before drilling begins, engineers conduct a thorough geotechnical survey to assess soil composition, groundwater levels, and load-bearing capacity. The site is cleared, leveled, and marked for pile locations using GPS or surveying tools.

A rotary drilling rig with a temporary casing or bentonite slurry is used to excavate the hole to the required depth. The method depends on soil stability—casing prevents collapse in loose soils, while slurry maintains borehole integrity in waterlogged conditions.

A pre-fabricated steel reinforcement cage is lowered into the borehole to enhance tensile strength. Spacers ensure proper concrete cover, preventing corrosion and maintaining structural durability.

High-quality concrete is poured using a tremie pipe to avoid segregation. The pipe ensures a continuous flow, displacing any slurry or water, and preventing voids. Concrete is cast until it reaches the desired pile cut-off level.

The concrete is left to cure for optimal strength (typically 28 days). Non-destructive tests (like PIT or sonic logging) verify pile integrity, while load tests assess bearing capacity.

Once piles pass quality checks, a reinforced concrete pile cap is constructed to distribute structural loads evenly across the pile group.

We provide high-efficiency, precision drilling equipment and technical support to ensure the success of mineral, geological, and engineering projects under complex global conditions.

Roller bits are essential components in modern drilling operations, widely used in foundation drilling, piling, bore pile,well drilling, and oilfield exploration. Designed to withstand extreme ground

What Are Bullet Teeth? Bullet teeth are essential wear parts used on drilling tools such as augers, drilling buckets, and core barrels in foundation and

What is an auger drilling? Auger drilling is a widely used drilling method in piling and foundation construction. It uses a helical screw blade, known

Pile Casing for Deep Foundation – Types, Applications & Installation Pile casing, also known as piling casing or casing pile, is essential in deep foundation

Want more product details? Send us an inquiry

Copyright by Meclead.com.